Food is the top priority for the people. In the past, if people didn't want to cook by themselves, they could only go to the store to eat or make instant noodles. Now, with three meals a day, you can use your fingers and rely on takeout to solve the problem; Not only can you enjoy steaming and delicious boxed meals without leaving your home, but you can also enjoy various fresh products from all over the country and the world, all of which are temperature sensitive products that require cold chain logistics for transportation. In cold chain logistics control, you may have seen different types of foodInsulation boxProducts, including plastic, foam, metal, wood, cloth and other insulation boxes. Among them, foam insulation materials are EPS, PU and EPP because of its light texture.

EPS Insulation boxIt is brittle in nature, easily damaged, and mostly used for one-time use. It is used for short-term and long-distance refrigerated transportation, with average insulation effect. In addition, there are additives during the foaming process, which is not environmentally friendly. Waste cannot be naturally weathered, and incineration treatment can produce harmful gases, making it the main source of white pollution.

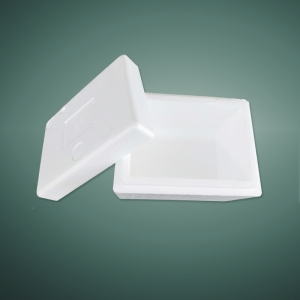

In addition, the EPP raw material itself is environmentally friendly and food grade, which can be naturally degraded and harmless to the environment. The foaming process is only a physical molding process without any additives. Therefore, the finished EPP insulation box is very suitable for food preservation, insulation transportation, and can be recycled and reused, making it very suitable for commercial purposes such as takeout and cold chain logistics.

The quality of EPP foam insulation boxes also varies. The raw material selection, technology and experience of EPP foam factory are all important factors that determine the quality of products. A good insulation box, in addition to its basic design, must have full and elastic foam particles, good sealing performance, and no water seepage (good EPP raw materials do not have this problem).

If you need an EPP insulation box or packaging, you can contact Qingdao Rongfa Insulation Materials Co., Ltd. for more information. We will also provide you with more suggestions based on professional considerations!

Sincerity is the foundation of technological innovation

Contact information: 0532-85239187 |

Mobile: thirteen billion five hundred and eighty-nine million three hundred and ninety-seven thousand seven hundred and fifty-two |

Address: Industrial Park, Ducun Town, Jiaozhou, Qingdao, Shandong Province |