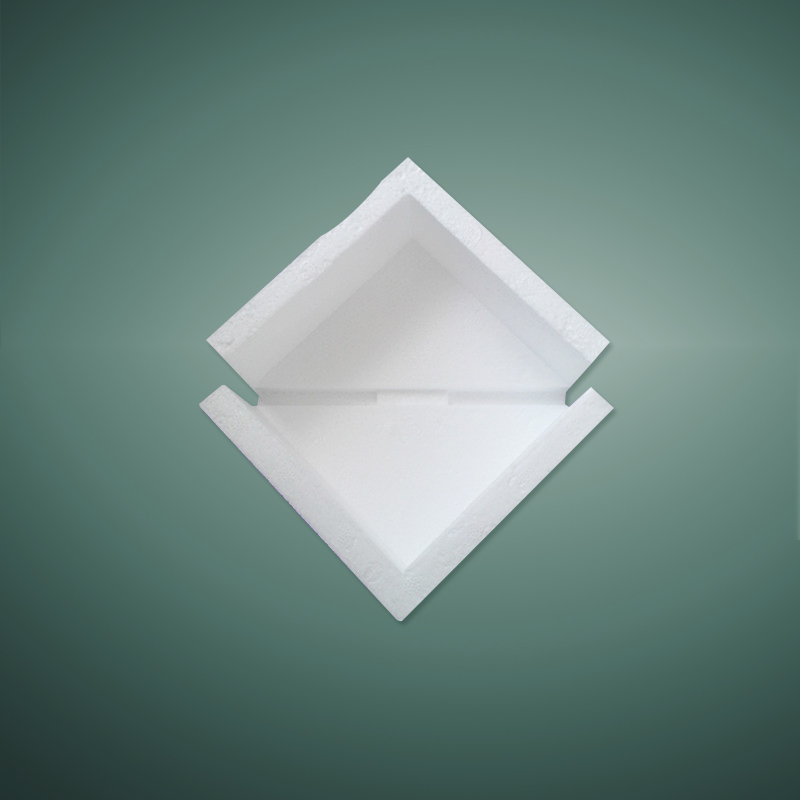

Foam box packaging, in short, is made of foam. Generally speaking, the foam packaging is mainly made of expandable polystyrene (EPS) raw materials by hot processing through molds. The packaging products produced are commonly known as "foam". Expandable polystyrene is an ideal packaging material that can be processed into various shapes and thicknesses of packaging products according to needs through molding processes. Under high loads, materials achieve cushioning and shock absorption through deformation, energy absorption, and decomposition, while also having insulation and insulation functions.

Foam packaging manufacturerAdvantages of the product:

1. Lightweight. Part of the space in EPS packaging products is replaced by gas, with 3 to 6 million independent sealed bubbles per cubic decimeter of volume. Therefore, it is several to tens of times larger than plastic.

2. Have the ability to absorb impact loads. When EPS packaging products are subjected to impact load, the gas in the foam is consumed and dissipated through stagnation and compression, and the foam body gradually terminates the impact load with a small negative acceleration, so that it has a better shockproof effect.

3. Good insulation performance. The thermal conductivity is the weighted average of the pure EPS thermal conductivity (108cal/m.h. ℃) and the air thermal conductivity (approximately 90cal/m.h. ℃).

4. Good sound insulation performance. EPS products are mainly soundproofed in two ways: firstly, they absorb sound energy and reduce reflection and transmission; The second is to eliminate resonance and reduce noise.

5. Anti aging and corrosion resistance. Except for long-term exposure to high-energy radiation, the product has no obvious aging phenomenon. Can withstand various chemical substances, such as dilute acid, dilute alkali, methanol, lime, asphalt, etc.

6. Antistatic performance. Due to the low conductivity of EPS products, they are prone to self charging during friction and will not affect the products of ordinary users. Anti static EPS products are applied to high-precision electronic products, especially large-scale integrated block structural components of modern electrical appliances.

Qingdao Rongfa Thermal Insulation Materials Co., Ltd. is a large-scale enterprise specialized in packaging and energy-saving thermal insulation materials in Qingdao, integrating the R&D, production and sales of EPS, EPP foam packaging products and thermal insulation materials.

The company has always adhered to the development concept of "independent innovation, quality first", market-oriented, combined with the actual needs of market development, the "RongFA" series EPS, EPP foam packaging products produced have a high reputation in the market, and continue to research and develop new packaging and energy-saving insulation materials.

Sincerity is the foundation of technological innovation

Contact information: 0532-85239187 |

Mobile: thirteen billion five hundred and eighty-nine million three hundred and ninety-seven thousand seven hundred and fifty-two |

Address: Industrial Park, Ducun Town, Jiaozhou, Qingdao, Shandong Province |